Bolzoni Standardizes Manufacturing Processes and Accelerates Innovation

Bolzoni is a leading global manufacturer of lift truck attachments and material-handling equipment.

Over the last 75 years Bolzoni has expanded their global footprint partially by acquiring smaller, local companies. With each acquisition a new set of IT systems and processes must be adapted to fit the organization. At the same time, Bolzoni’s organizational strategy has become more complex.

“Historically our products have been mechanical products, which we sold directly to forklift manufacturers or end-users,” said Pietro Foroni, quality & engineering technical director.

“Now, we are entering a new business phase in which sensors, controls, software, and I/O connectors are becoming more and more important in linking products together as unique solutions for our customers.”

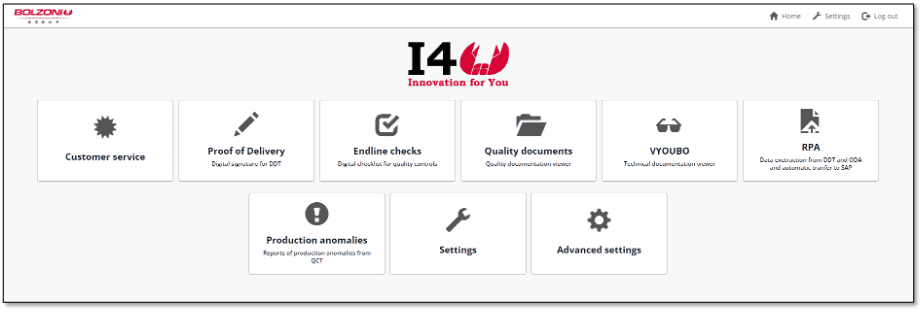

In this new phase, Bolzoni needed a software delivery platform that could flexibly handle their integration and connectivity requirements. In late 2022, they adopted the Mendix low-code platform to align their systems of record across the product lifecycle.

Today, they have successfully delivered nine Mendix applications that streamline processes such as quality checks, customer service reporting, and product delivery.

Strategic Alignment and Integration

As Bolzoni has expanded their business in the US, China, and Brazil, each new plant comes with its own processes, technology, and particularities.

“About 20 years ago we started aligning all of the processes in the engineering department,” said Foroni, who is a mechanical engineer by trade. His team oversees products from prototyping and welding to testing and post-sales.

That’s where IT director Stefano Terzoni comes in. His team’s strategic purview focuses on IT systems, cybersecurity, and IT innovation.

“For us, it became very important to have a tool that could integrate our core systems and increase our innovation — and we needed this to be the same tool,” said Terzoni.

Over the last two decades, Bolzoni has consolidated their technology stack to three core systems for their main business processes:

- Siemens Teamcenter PLM for product development

- SAP for operations

- Salesforce for customer relationship management

Bolzoni looked to the options within the core system landscape: SAP Fiori and Siemens’ low-code development platform, Mendix.

“We evaluated SAP Fiori, but we realized that it was not as simple for our team members to learn as a low-code or no-code platform. We also saw that a low-code platform could significantly reduce our development time, which would help us to address the challenge of shadow IT,” Terzoni shared.

While speed of development and developer uptake were points for Mendix, Bolzoni had to look critically at the platform’s compatibility with SAP.

“We discovered quite quickly that integrating SAP with Mendix is very, very simple. And of course, we knew that Mendix would integrate easily with Siemens Teamcenter,” Terzoni noted.

In Q1 of 2023, Bolzoni selected Mendix as their innovation tool of choice and within a few months would set their first low-code applications live.

People and Partnership

Terzoni began establishing a low-code development team starting with two developers and an expert implementation partner, Netribe.

Partnering with Netribe allowed the Bolzoni team to co-develop alongside experts, expedite the delivery of early projects, and lay the foundation for a more self-sufficient future.

“This is our typical approach with customers, and I think one of the powerful points of Mendix,” said Luca Villani, project manager at Netribe.

Marco Marchesi is an engineering system specialist and was one of the first in Bolzoni to start using Mendix. “This was my first experience with a low-code environment. I always developed with Java or C# before,” he said.

“I went to the Mendix Academy, starting with the basic course and then moving up to the advanced. We were experimenting with projects before we selected Mendix. Once we kicked off our first project with Netribe we set up the basics. They taught us about entities and how to implement things like single sign-on. From there we learned by practicing on our own.”

The Netribe team also shared their knowledge on leveraging standard, reusable building blocks from the Mendix Marketplace. These components and functionalities are professionally maintained, further reducing the burden on Bolzoni’s lean development team over time.

“Whenever we work with customers, we try to use everything that Mendix has to offer,” said Villani. “If something goes wrong or there is a necessary security update, that is managed by Mendix. The customer just has to upload the new version from the Marketplace, and it is all set. The Marketplace is one of the best things that Mendix offers, because everything is just there.”

Netribe supported Bolzoni in establishing reusable UI components and leveraging pre-built connectors to SAP, Teamcenter, and AWS to expedite development.

Federico Balestrieri is an SAP technical specialist and the second Mendix developer at Bolzoni. Given the prevalence of SAP in their processes, Balestrieri reflected on the importance of establishing a seamless connection early on.

Leveraging every possible mechanism to accelerate the software development lifecycle changes the way that Bolzoni can test and learn as new ideas arise.

“Low-code allows us to develop in a short time. During the innovation process, we need to consider failures,” said Terzoni.

“This is normal and will happen. If we’ve only taken a few days to develop a solution with Mendix instead of a few weeks or months, we can accept those failures in a different way and move on quickly to see what else might work.

Transparent Quality Management

Bolzoni’s goal for Mendix is to shorten the distance between their people, processes, and core systems.

With vast amounts of information existing in Teamcenter and SAP, shop floor employees didn’t always have the right interface to access these systems properly.

Their team has delivered nine applications to date which are:

- Digitizing shop floor processes, which reduces manual work and improves product quality.

- Providing greater transparency and enabling data-driven decision making.

- Streamlining innovation, as the applications are flexible in nature and can leverage the vast ecosystem of Mendix services and connectors to other valuable systems.

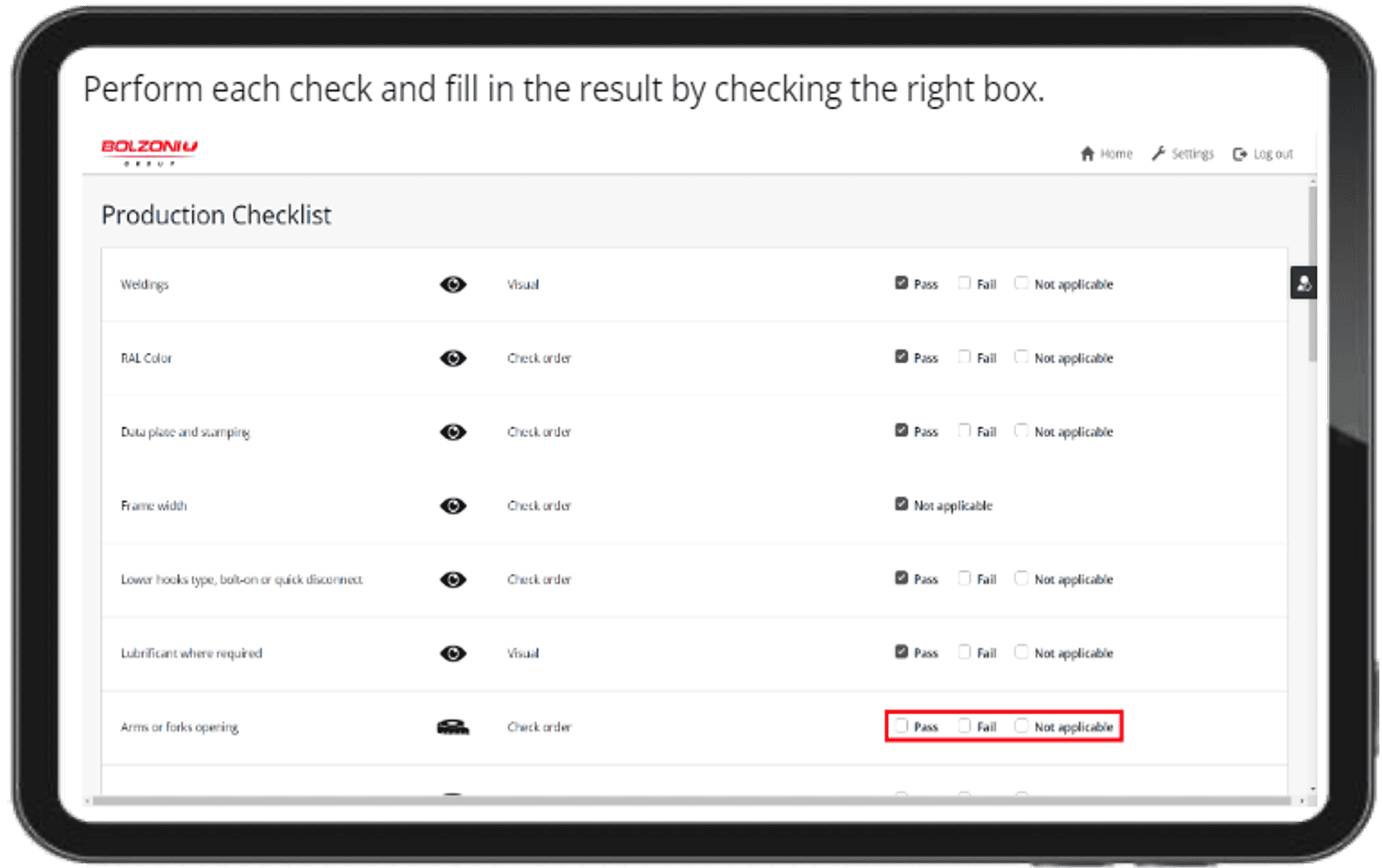

The business-critical process of quality checks was historically manual and paper-based for Bolzoni. Shop floor operators would record the checks on paper, scan the document, and then upload it to their ERP system.

Bolzoni’s first Mendix project was developing their Quality EndLine Checklist application. The application was developed in just two weeks and went live in early 2023. Today, it is used on the shop floor in Italy and will be rolled out globally to all shop floor operators in the next few years.

The new application is accessible on a tablet, where shop floor operators scan the product barcode for an initial verification. They can then populate the necessary information — such as the quality of the welding or oil calibration — which is then automatically reflected in SAP Quality Management (QM).

“The process is now digitalized with Mendix, and it is completely integrated with SAP QM, which was very important for us,” said Terzoni.

“The application uses three calls to SAP. One to check if the serial number is correct, one to retrieve the list of controls that need to be performed, and one to change the status of the checklist in SAP. It then attaches a PDF generated by Mendix with the results,” said Balestrieri.

Digitizing the experience in Mendix also affords the team greater flexibility to adjust as processes evolve over time. “We made the application in a way that when we add new controls on SAP, the list that the operator has to complete is dynamic based on the attachment,” he added.

The team is experimenting with integrating AI and machine learning capabilities by way of pre-built AWS connectors from the Mendix Marketplace. With this service, when users upload supporting images to Quality EndLine Checklist, Amazon Textract can process and route them accordingly.

Quality EndLine Checklist is now a fully integrated and digital experience that is increasing data quality and transparency.

“The biggest advantage of Quality EndLine Checklist isn’t just removing the paper and manual activity,” said Foroni. “If a check fails, the product is not allowed to move to the next step until that failure is resolved.”

“Now the company has data that we can analyze and make decisions with. We have greater traceability of all the failures. We are in the process of developing a new Mendix application that will compare the data on failures across departments. This will help us to be more proactive in identifying areas of our shop floor processes that need improvement.”

Enabling Process Innovation

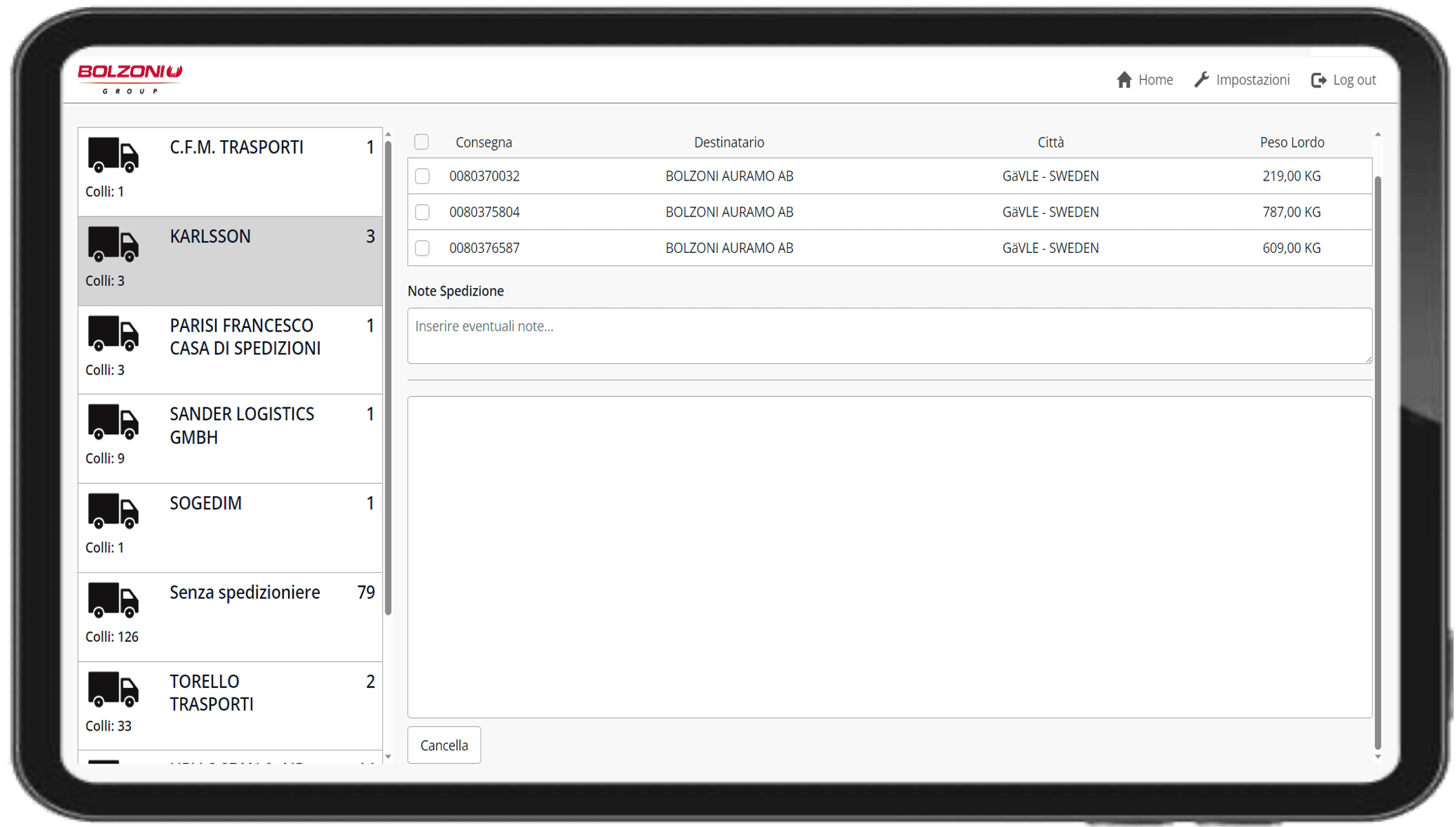

Another paper process Bolzoni quickly addressed was the collection of delivery notes and signatures. Initially, another developer was tasked with developing a solution in SAP Fiori, but there were challenges at the point of signature.

“After testing this out for two weeks in Fiori, we decided to shift the process to Mendix. In less than a week we rebuilt the application,” said Terzoni.

In the new Delivery App, operators select the shipping method and then sign off. Their signature is then archived in SAP and an external legal archive.

Centralizing systems and processes also comes in the form of the Bolzoni Innovation Portal, which was developed in early 2023. The portal is a central gateway to any innovation-related applications that the IT team delivers, including all of their Mendix solutions.

In another areas Bolzoni has been successful in reducing their dependency on third-parties and black box systems. One instance is their new Technical Documentation portal used by the engineering and quality departments, which was delivered in just one month with Mendix.

This Mendix application replaces a technical portal that was custom developed by an external consultant. As it was a non-standardized app, it was difficult to maintain over time.

“The custom tool created security issues for us. For example, every time a Windows update was released, the tool would become blocked. We would have to model the quality documentation in another system,” said Terzoni.

The Technical Documentation portal integrates 3D models from Teamcenter and data from SAP into a single view owned and maintained by Bolzoni IT.

“We are connected to a database of files such as PDFs and images, as well to an SQL database where we get all of the information from Teamcenter,” said Marchesi.

A Foundation for Transformation

Just over a year after implementing Mendix, the Bolzoni team is proud of the progress they have made towards becoming a more integrated and innovative organization.

Foroni believes strongly in evangelizing what is possible throughout the organization to keep their momentum. First, by selecting the right people to be involved with software development. He feels that the team has remained motivated because they feel a sense of ownership and opportunity in the work they are doing.

“The next step is to share the results of development with everyone in the company so they can see that there is an advantage in using these new tools. When we have our users on the shop floor experimenting with new features, that helps us make even better solutions,” said Foroni.

“The normal resistance you see from people is when they are not convinced that new systems will be advantageous for them. But if you can show them how the technology will simplify their life, you can win them over,” he added.

Mendix enables Foroni and Terzoni’s areas of expertise — business needs and technological capabilities — to converge into meaningful software solutions. The successful foundation laid in their partnership is making way for new ideas in other areas such as customer support, logistics, and order management.

“We managed to reduce the time to get new solutions to our users and increase efficiency. It’s also very important to have a standard way of developing where we can ensure security. With Mendix, we’ve been able to meet the strategic pillars we have outlined from the start.”

Mendix is a Siemens Business.