How to Better Manage the Cold Supply Chain with Mendix and AWS

According to a recent United Nations (UN) report, around one-third of all global food production is wasted annually. This loss contributes some 4.4 billion tonnes of CO2 equivalent to our planet per year; about 8% of all annual greenhouse gas emissions.

Fruit and vegetables, meat, fish, dairy and many other perishable goods need temperature-controlled transportation to maintain product safety, quality, and freshness. But according to the UN report, inadequate cold chain logistics cause the loss of nearly half of various temperature-sensitive foods every year.

In the life sciences industry, failure to maintain optimum conditions not only leads to wastage. It can risk human life. In one case, some 100,000 Covid vaccinations and other drugs were lost, when temperatures rose in a cold storage unit.

Today, a number of organizations have built applications on Mendix to help them ensure effective cold chains and supply chains. For example, Farm Trans provides an extensive ‘connected’ logistics supply chain to the food industry, while AntTail provides transparency in the pharmaceutical cold chain from manufacturer to patient.

This post is written in conjunction with Viktoria Semaan, Senior Partner Solutions Architect at AWS, and Erika Arena, Principal Industry Lead at Mendix.

Getting grips with cold chain systems

Gartner suggests designing and managing effective cold chains demands collaboration amongst a broad set of stakeholders and requires significant in-house expertise. That’s surely true, but much also boils down to the smart use of modern technologies, including Internet of Things, Cloud computing, artificial intelligence and machine learning. Then there’s also the challenge of managing complex integrations. All this places tremendous pressure on logistics functions and hence on IT teams which are already being asked to do more with less.

No one solution that can easily address the requirements of cold chain distribution across all industry niches. Many organizations have tried and struggled to manage the chain with broad enterprise solutions. Others have attempted it with siloed solutions such as for works management, transportation, and procurement. Most fall short in one way or another, often lacking freedom for customization or missing integration and data exchange capabilities. Most struggle to support frequent change, presenting severe headaches to logistics leaders, especially those in dynamic business environments.

Today, newer approaches have evolved to make custom development, system integration, and adaption for change easier. Low-code development platforms are helping organizations build their very own purpose-built applications. These applications enable them to better manage their supply chains, cope quickly with change, cut waste and the cost of waste and outpace slower commercial competitors.

Building solutions with low-code

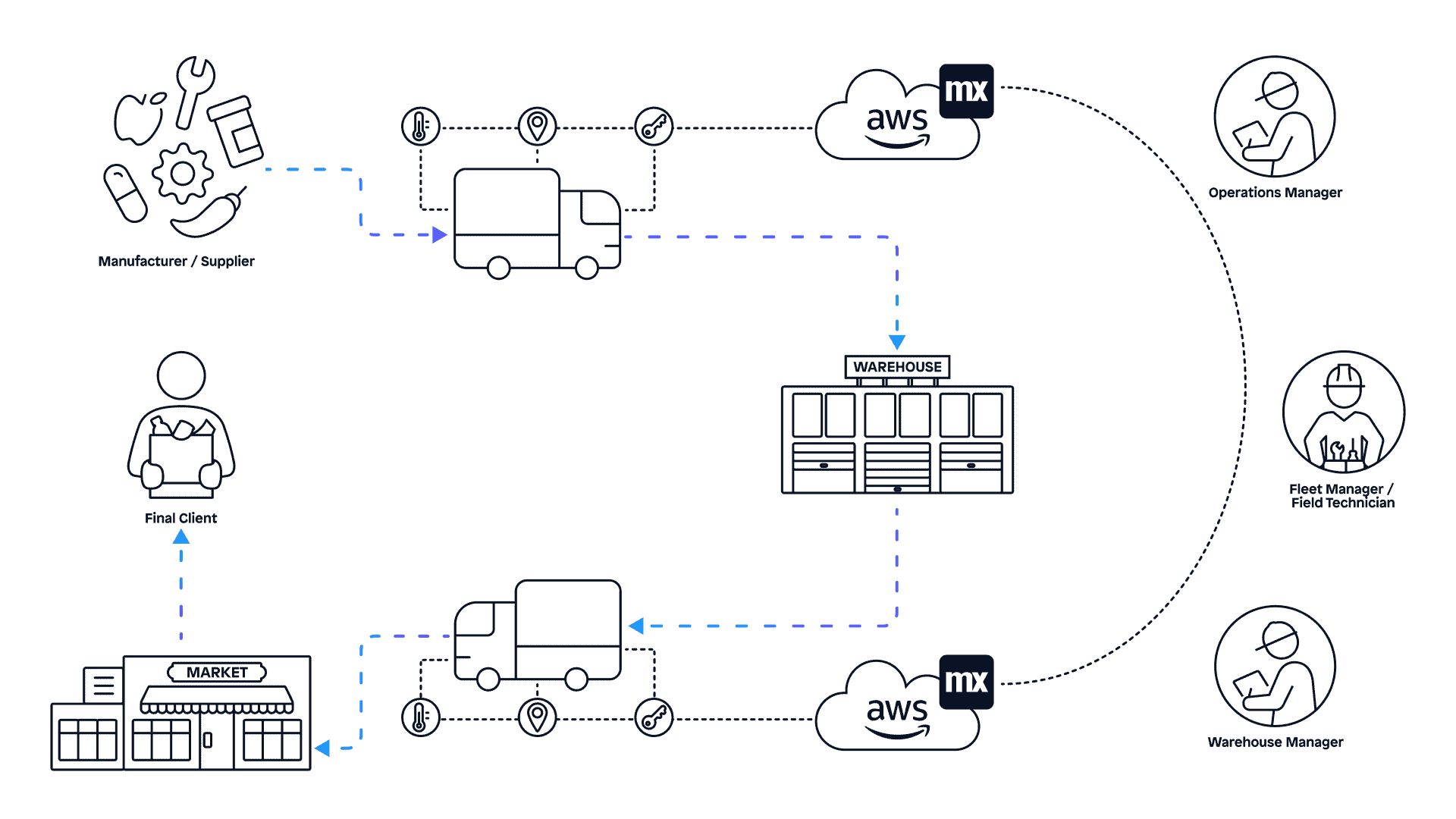

Before we look at building solutions with low-code, let’s first understand the complexity of what’s involved. Not only must an effective solution support every step from product collection through to timely delivery. It must also monitor product location, temperature, and other variables then provide this insight in near real-time to logistics managers, quality controllers, operations and customer managers and other responsible parties. It must also be capable of swiftly alerting field service technicians when conditions suggest equipment failure threatens a shipment. Then, as well as all this, implementation of systems also requires juggling with industrial equipment (sensors, actuators), data management and analytics and with earlier alluded complex system integrations. Addressing all this through traditional application development is often lengthy, effort-intensive, and costly. But don’t be put off. The answer lies with low-code.

In contrast to traditional code-based software development, low-code platforms like that offered by industry leader Mendix enable developers to create applications at speed. Out-of-the-box templates, building blocks, connectors, and prebuilt integration modelers allow developers to build in days what used to take months. Low-code approaches remove much of the complexity, allowing IT teams to focus on delivering business outcomes, rather than spending so much time coding or building integrations.

Implementing a cold chain system with Mendix on AWS

Many organizations know the potential wins to be had from harnessing disruptive technologies like IoT, AI, ML and Big Data. But many have not had the skills, time, and resources to take advantage of them. Now they can.

Through the Mendix/Amazon Web Services strategic partnership, the Mendix enterprise low-code platform boasts a broad and deep integration with AWS services. Organizations can now develop cloud-native intelligent applications on Mendix, powered with AWS services like IoT, AI, ML and Analytics, and bring the results to market faster than they ever could before.

You can create cold chain management applications that are much better than those you have today. You can do so more easily than ever before, and bring them to market quickly.

Mendix on AWS in action

In this video demo, you’ll see a smart app being created to improve the logistics of transporting perishable goods. It’s an example of how developers using Mendix can leverage AWS services to swiftly build intelligent solutions.

The video shows GPS-enabled real-time traceability, monitoring, and control through a Mendix app. The app subscribes to AWS IoT Core to receive data from sensors attached to the truck and to each container. The sensors report the current container’s GPS position and environment-sensitive attributes for each compartment. With one click, operations managers can check the details of transport routes, container details (integration with ERP systems), and critical condition attributes and take action in the case of abnormalities.

Real-life stories

Mendix for Life Sciences – AntTail

AntTail offers the pharmaceutical industry the ability to track sensitive medicines as they move through the cold chain, right from the factory to the customer. The temperature of many medicines is vital to their effectiveness and to meeting quality standards and regulations.

AntTail’s service utilizes IoT sensors and an app built using the Mendix platform. The app breaks through data siloes to enable pharmaceutical manufacturers, health providers, and logistics companies to continuously monitor medicine storage temperatures. In the event a medicine is exposed to freezing temperatures, AntTail gives interested parties up to an incredible 55 percent greater probability of identifying this occurrence and where in the supply chain it happened. The responsible party can address the matter for future shipments.

AntTail can even monitor whether patients are storing critical medicines correctly. It has a 98% success rate at spotting instances of incorrect storage temperatures and notifying patients so that they can (for example) adjust their fridge.

Mendix for Food – Farm Trans

Since its launch in 1987, Farm Trans has grown from a local company to a European logistics service provider, specializing in bulk and conditioned (temperature-controlled) food products. Its business strategy welcomes innovation and today it provides connected services to manage customers’ local and global logistics more efficiently.

Driven initially by a need to respond to a changing regulatory framework caused by Brexit, Farm Trans decided to digitize its paper-based administrative processes. Selecting the Mendix development platform, it built its app suite, the “Logistics Management System,” in just six months. The application streamlines logistics processes and connects suppliers, partners and customers.

“By leveraging the analytic capabilities of our Mendix-built application, we now have the opportunity to serve partners in a more streamlined, customer-friendly way. The new application enables us to act on our data very fast,” says Michiel van Gerwen, team lead, Connected Services, at Farm Trans. “For instance, during the Covid-19 pandemic, we were able to suggest more economical transport patterns to our customers. Margins in logistics are slim, so these suggestions are very valuable to our transport partners and customers.”

Accelerating digital transformation through Mendix on AWS

Across industries, Mendix enables organizations to improve operational effectiveness, customer experience and to reduce cost. Powered with 200+ AWS services, Mendix gives organizations a complete low-code enterprise platform to rapidly develop cross-domain business outcome driven applications, keeping your digital transformation thread unbroken from strategy to planning to design to development. Beyond the enterprise, Mendix allows you to reach back into the supply chain and forward to the consumer, engaging more of the value chain within your digital fabric.

Want to learn more?

Check out our on-demand webinar to see the possibilities of the Mendix platform powered by AWS services. We have prepared a demo in which you’ll see a smart app being created to improve the logistics of transporting perishable goods. Watch it here.

Or read the blog Viktoria Semaan wrote for AWS: Mendix and AWS Drive Development of Cold Chain Logistics with Environmental and Economic Goals