Master the 4 Ms of Manufacturing with the Lean Daily Management Suite

A shop floor supervisor walks past a machine press and notices that one of the activation buttons is taped down. “What’s the tape for?” the supervisor asks the operator.

“Well, to activate the press, I’m supposed to hold down two buttons at once,” the operator answers. “But that wastes time reaching out with both hands. So I’ve made things more efficient by taping down one of the two buttons. That gives me one more hand to work with.”

“You’re going to have one less hand to work with if you get it caught under the press,” the supervisor retorts. “That’s why there are two buttons!”

Saving time and increasing efficiency while keeping the shop floor running safely is what every factory strives for. But not by taping over safety features. It is done by ensuring that shop floor operations are conducted in the best way possible to meet target objectives. That is the defining principle of the Lean Daily Management process. Helping manufacturers conduct their shop floor operations is also the objective of the Mendix Lean Daily Management Suite.

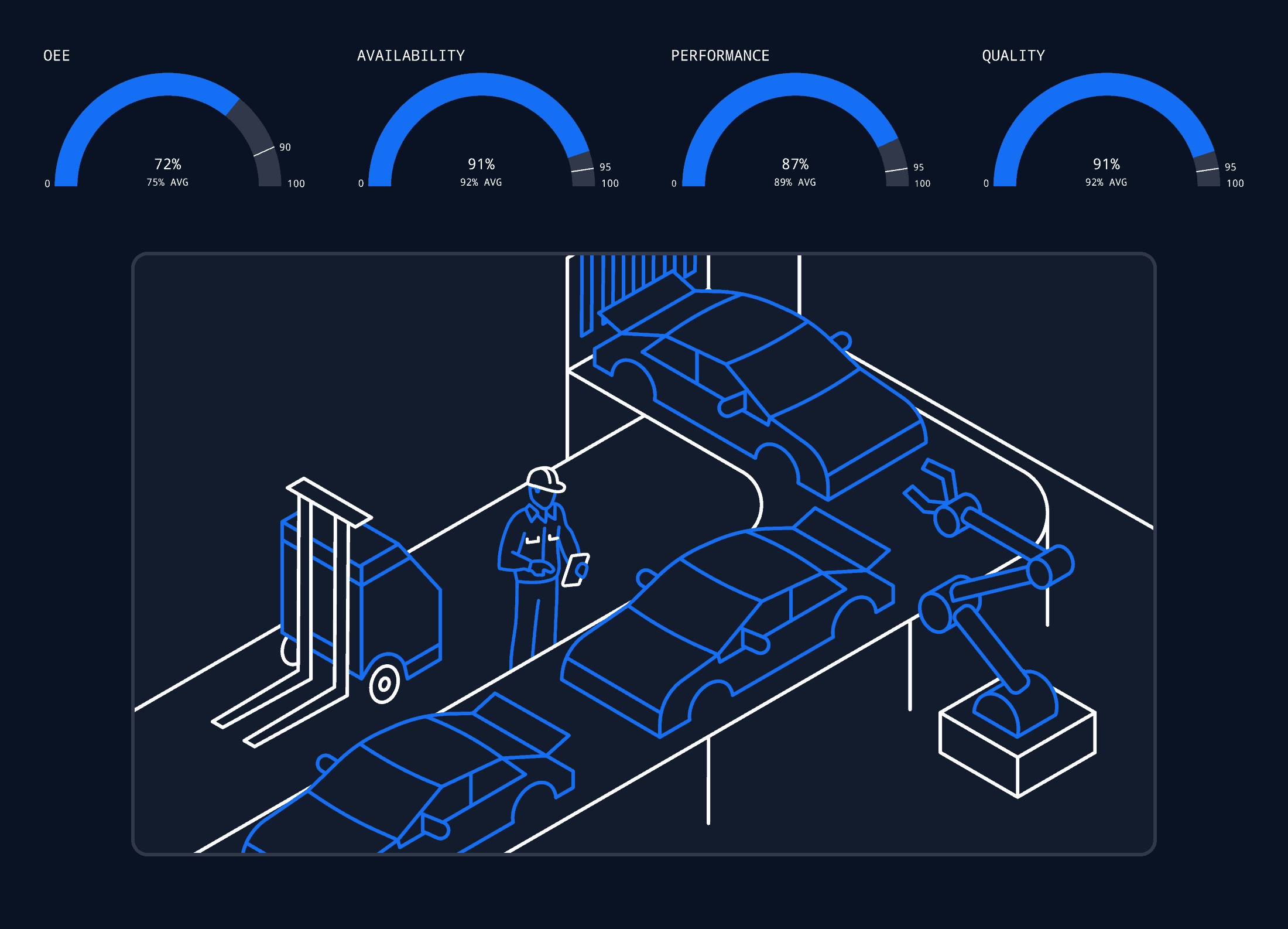

A 3D View of Your Shop Floor

A visual management tool for day-to-day shop floor operations, the Lean Daily Management Suite is a set of five low-code applications, services, and software. You can easily modify the components of the suite to create solutions perfectly tailored to your unique industry and organizational requirements.

The main application provides production line supervisors with a 3D model of the shop floor so they can monitor the status of all their work centers. Traditionally, line and shift supervisors have received their shop floor management data through paper systems or Excel. Receiving it in the form of 3D visualization gives them more insight into and control over day-to-day operations.

The combined capabilities of the Lean Daily Management Suite help manufacturers to:

- Collect and analyze plant operations data

- Maintain equipment

- Keep plants safe and operational

- Manage shifts and workforce

- Transfer knowledge between shifts

An Eye on the Four Ms

By giving manufacturers situational awareness into every operation on the shop floor, the Lean Daily Management Suite lets you take immediate action on urgent or persistent issues. Most of the issues that the suite will provide alerts on will fall under one of the 4 Ms of manufacturing: Machine, Man, Material, and Method.

Machine

These issues involve machines on the factory floor equipped with sensors. The Lean Daily Management Suite feeds the data from these sensors to the supervisor to help them quickly diagnose problems and devise solutions. For instance, if a segment of the production line becomes backed up, the supervisor can find an underutilized segment and reroute production through it.

Man

These are workforce issues. The suite keeps track of everyone scheduled for every shift along with their skills and availability. It also works hand-in-hand with an organization’s workforce management system to provide the most suitable replacement options if a worker is unavailable for a shift due to sickness or other last-minute emergencies.

Material

Any issue involving the raw materials required for production fall under this category. With the Lean Daily Management Suite, the supervisor can track the quantity and the quality of the material needed to feed the production line. If there is not enough material on hand to meet the production quota, the suite will alert the supervisor at the beginning of the shift so that they can get a jump on securing additional supplies.

Method

These are operation issues, ones that stem from operators following the wrong or poorly designed protocols. The example of the press operator undermining safety protocols by taping down one of his activation buttons would certainly fall under this category. Another example might be a shift employee forgetting to submit a necessary process checklist. The Lean Daily Management Suite can keep supervisors tuned into shop floor tasks such as these so they can be quick to pick up on any problems involving production methods.

Better Together

The power of AWS and the speed and efficiencies of Mendix are a natural fit, which is why the companies have been collaborating since 2015. This collaboration helps manufacturers use Mendix templates to quickly and easily build apps and then supercharge those apps with the intelligent automation services of AWS.

The Lean Daily Management Suite lets you tap into the full power of AWS. The suite uses AWS IoT Twinmaker to take in data directly from an IoT system like Siemens Insights Hub or AWS IoT Sitewise. The suite includes Mendix widgets to let you make the best use of the 3D visual data from AWS IoT Twinmaker and shop floor video footage coming in through Amazon Kinesis Video Streams.

Keep Composed

Agility and adaptability are top concerns for manufacturers. That is why so many organizations are taking an interest in composability. The ability to compose applications from simple and interoperable building blocks, rather than build every solution from scratch, is the key to being able to react swiftly and nimbly to the marketplace.

The Lean Daily Management Suite is completely modular. You can configure its apps and services to match your ever-changing organizational needs. And it is designed to connect multiple systems, such as your manufacturing execution or product lifecycle systems. There are endless possibilities for how you can compose this Lean Daily Management Suite to keep it relevant to the strategic goals of your organization.

Taped-down buttons are not the most vexing problem manufacturers face. Not having a comprehensible and data-rich view into their shop floor operations is. The Lean Daily Management Suite gives you that view in a way that is flexible, composable, and compatible with AWS. To learn more, visit the Mendix Marketplace.