Crafting a Digital Thread in Aerospace & Defense with Low-code

Manufacturers around the globe are facing increased competition, a need to reduce operational costs, and changing customer expectations. Not only do these challenges require digital sophistication, but they are expected to be addressed more quickly than ever before.

According to PWC, in a survey of 2,000 manufacturers, 86% expect their digitalization efforts to reduce costs and add revenue in the next five years. Today, not delivering a more connected, digital product experience for both employees and customers simply means money left on the table.

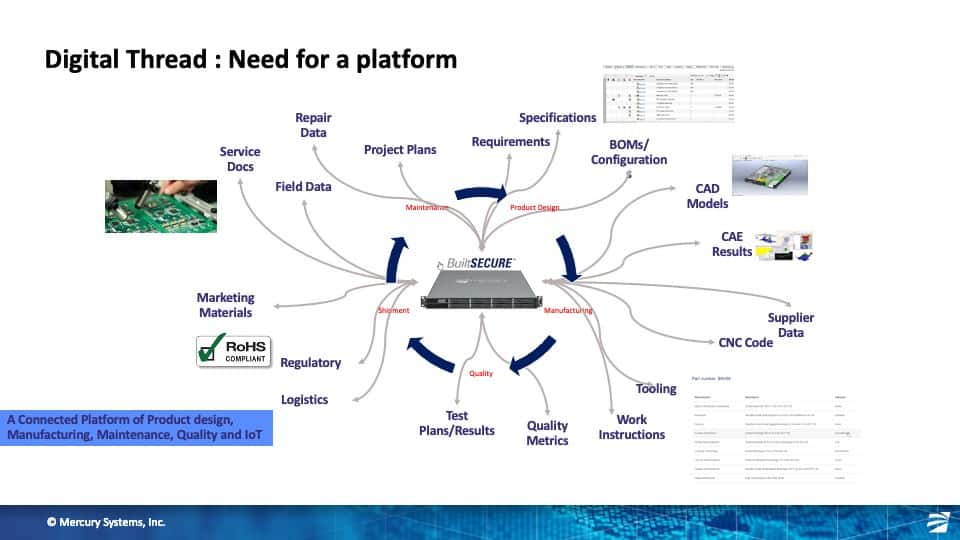

Mercury Systems, an American multinational technology company, supplies defense contractors with mission-critical technologies from radar testing to display systems, needed a solution that could deliver digitalization projects at the highest level of security. The team was already underway with their Digital Thread initiative – the connection of disciplines that provides a visual interpretation of complex data sets like supplier data, bill of materials, CAD models, CAE results, specs, field data, and project plans.

At Mendix World 2020, Director of Application Engineering at Mercury Systems, Anu Mishra, and CEO of CIGNEX Datamatics, Harish Ramachandran, outlined their path to leveraging low-code within a DevSecOps architecture to start delivering a digital thread.

Ultimately, engineers needed a better way to connect with other teams and access data from siloed platforms to ensure a better product outcome.

“And we realized that we needed a merging of all these different technologies… [and] a common interface that could link all bodies of product knowledge together.”

A Complete Low-code Platform in a DevSecOps Architecture

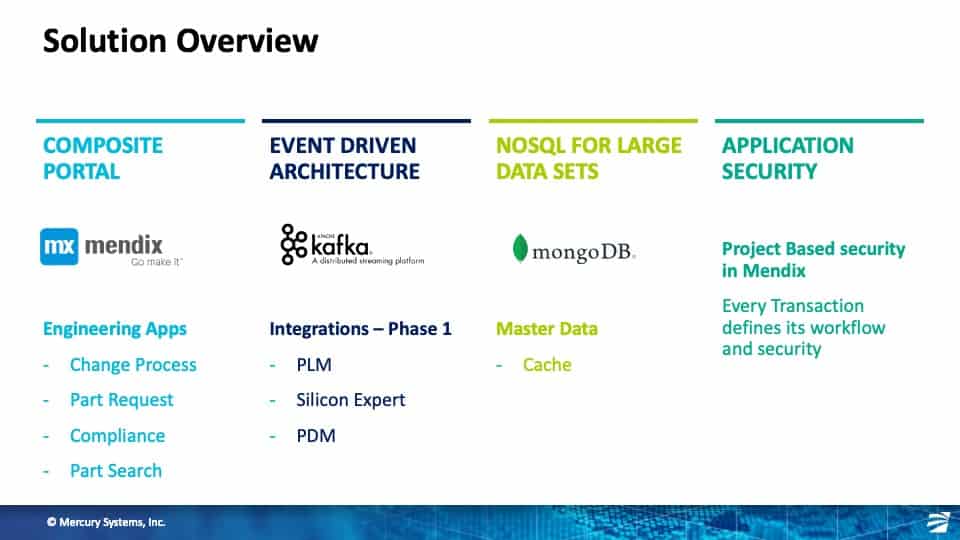

Within the parameters of Mercury Systems’ DevSecOps IT environment, the low-code evaluation process revealed that Mendix could deliver on essential criteria such as:

- Delivering the right solution in a highly complex environment: Mercury Systems has several disparate and costly systems in play. For instance, a Mechanical Lead lives in a CAD platform and a Project Manager lives in JIRA, but both need a place where these functions come together and allow for collaboration in consistent and contextualized data.

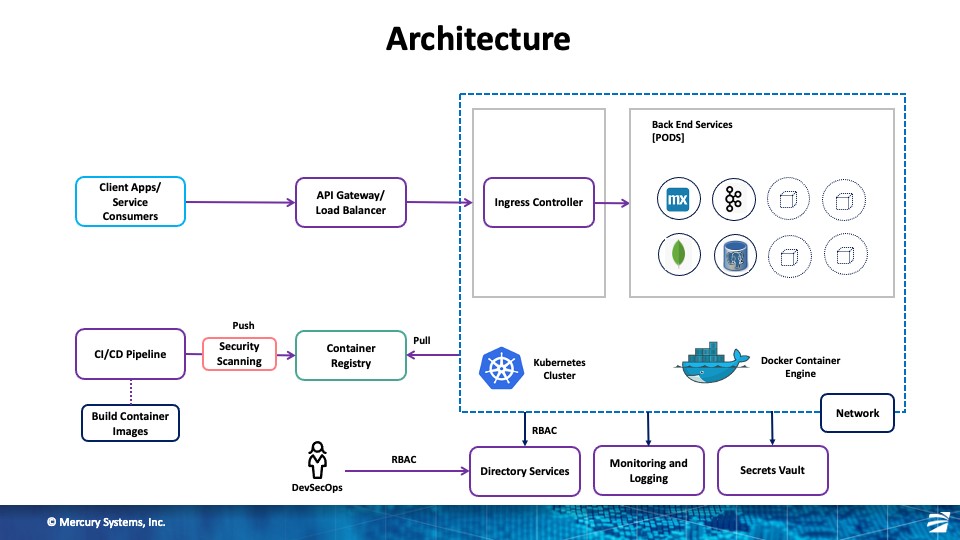

- Offering robust security and governance: Based on their industry and commitment to DevSecOps, a platform that imposed a single point of failure was a non-starter.

- Supporting a cloud-native environment: Closely tied to point two, to meet security and compliance standards, a partner must operate within Mercury’s on-premise cloud environment. Additionally, working seamlessly with Kubernetes ensures this security at scale.

By meeting these requirements, Mercury Systems has been able to reap the acceleration benefits of a low-code platform without needing to compromise on security. Further speed of development was realized as Mendix easily integrated with Mercury’s engineering systems

In the future, rapid development will be improved by way of Mendix Data Hub, which broadens the ability for more domain experts to visually integrate data sources like Teamcenter without being data integration specialists.

Beyond integration, the team at Mercury Systems can take advantage of a wealth of pre-built connectors and widgets, like CAD visualization, for greater reuse as they continue to scale their portfolio.

Tackling High Complexity

After identifying the right solution partner, Mercury Systems moved quickly to deliver on their Digital Thread Project, unifying a highly complex web of PLM systems.

“Digital Thread has ramifications across organizational functions, roles within programs, [and] how we connect all different disciplines,” says Mishra.

“How do we maintain this information as it moves across different phases [of the product lifecycle]?… Where do we connect the dots and build layers of customization on PLM systems? Do we build layers of custom workflows on our planning tools like JIRA, or do we build our layers of customization on PDM systems?”

“We’re marching towards model-based systems engineering, which evolves the need to connect these simulation tools, PLM systems and CAD systems together.” he continued. “[With] so many different applications and the user sets involved here, we needed something fast. Finally it was clear that we needed a local platform.”

To prove out the efficacy of low-code, Mishra and his team enlisted the help of a partner, CIGNEX Datamatics, to deliver a high-impact, but lower complexity solution before scaling up. “We created a skillset matrix tool within a week and we successfully rolled it out,” said Mishra, “and between two weeks we had something out there in production.”

Based on the success of this project, the team had the runway to scale up.

Putting the “Sec” in DevSecOps

A single interface across these groups, combined with project-level controls, made it easier to implement custom workflows across projects without running afoul of strict security parameters.

Mercury Systems was moving towards project-based security, and in Mendix this meant every transaction defines its workflow and security, and a business process becomes a project with its own controls and defined stakeholders.

“This security layer is on top of whatever else you would normally do with respect to identity-based access and permissions and everything else that exists within the Mendix environment today. So, that’s what made the whole application environment more unique,” said Mishra.

“We were looking for a platform that could actually help us realize this new architecture, as opposed to having a fixed set of permissions based on the rules. We did want that to be something that’s available at a record level. And that’s what we enabled with Mendix.”

“We extensively use the Docker Mendix buildpack,” Ramachandran added. “We do this offline because everything that you see, including the CI/CD pipeline, is all running within a secure environment, which basically means that it’s going through two firewalls.”

“Jenkins is running our build pipelines, reducing some security scans with tools like WhiteSource, and then it will subsequently republish the containers into our private registry, which is our own JFrog Artifactory repository,” he continued. “And that’s what the Kubernetes cluster will see, Docker images for deploying or for scaling any of these kinds of application environments that we have here.”

Scaling Towards Innovation

With better collaboration, ensured security, and a complete architectural vision, Mercury Systems is positioned to scale out their Digital Thread initiative while adhering to their DevSecOps philosophy. The completeness of the Mendix platform is already opening new opportunities for innovation.

With pre-built connectors in Mendix and the release of Data Hub, further digitalization can be achieved with greater speed – and that is exactly where the roadmap is headed. Mishra and Ramachandran’s teams plan to:

- Extend low-code usage beyond engineering tools and applications

- Complete their automated test suite

- Make the leap to CAD visualization and Data Hub

“Once we have built the physical product with its digital connections, we can leverage the wealth of information and apply machine learning services to improve our products,” says Mishra.

Considering the low rate (just 5%) of industrial companies actually implementing smart technologies in their manufacturing process, the machine learning and CAD visualization solutions that Mercury Systems is developing are a big step towards differentiating their process and products, and ultimately realizing the ROI of digitalization with low-code.