How to Craft Digital Manufacturing Processes at Speed

As a manufacturer of vinyl, performance polymers, foams, and performance fibers, Kaneka Malaysia is a part of many people’s everyday lives with a motto that says, “make your dreams come true.”

Established in 1995 as part of the larger Kaneka Corporation, Kaneka Malaysia’s 635 employees work on 98 acres’ worth of facilities to ensure top-quality products and goods for customers all over the region. Their vision is to become a market leader by empowering employees and continually improving their technology and processes.

Recently, Kaneka committed to a digital transformation project designed to bring automation and better data to their manufacturing processes in order to drive both efficiency and employee empowerment.

Hiroyuki Nishimoto, Managing Director, Wan Rosli Wan Ahmad, Manufacturing General Manager, and Norshasheema Shahidan, MIS Manager, all from Kaneka, presented their journey at Mendix World 2021.

Creating Automation with Digital Resources

When the team at Kaneka decided to replace legacy applications and revitalize their processes, they identified several key issues that they knew they would have to tackle:

- ROI: Kaneka’s leadership wanted to see a fast return on investment for the business, and, while investing in a ready-made solution was an option, the upfront cost meant a potentially long wait for a positive return.

- Lackluster market solutions: Building something that could both be custom to their needs and encourage their employees to realize their ideas digitally. An off-the-shelf solution would “not help to develop our employees to become creative and innovative in transforming their work culture,” described Wan Ahmad.

- Data management: At that time, a substantial amount of data was being held in either hard copy, email, or personal files. This led to long lead times for reporting and analysis and elongated the time needed to make data-driven decisions. Any technology solution would have to provide a safe, efficient way to gather and manage data.

- Limited resources: Since many of Kaneka’s processes were entirely manual, introducing technology would be an entirely new experience. Wan Ahmad said, “A lot of effort was done in promoting the potential of it and to gain trust from the stakeholders.” Initial buy-in and early results could quickly demonstrate value.

Building a Low-code Powered Roadmap

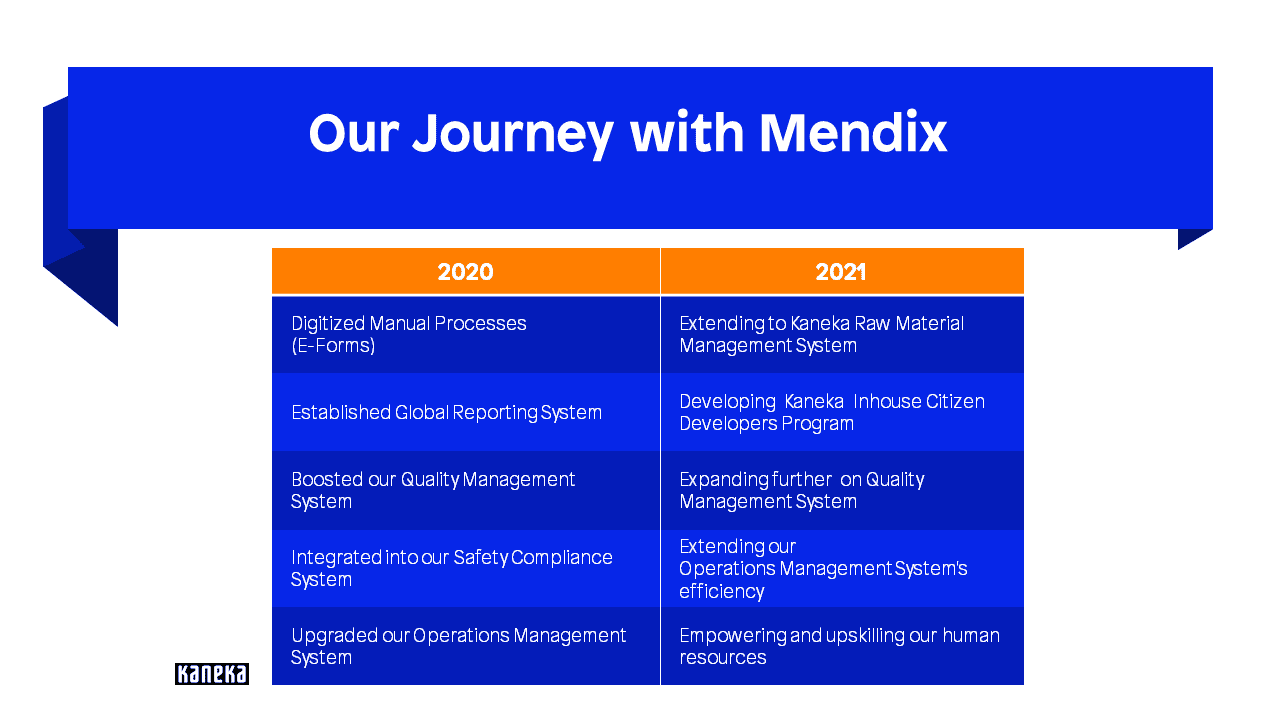

Low-code wasn’t on Kaneka’s radar when they began their digitization journey in 2018, but a Gartner article on low-code demonstrated the value and speed it could offer. Kaneka quickly contacted Mendix and Orangeleaf Consulting (a Malaysia-based Mendix partner) and started their journey.

The first steps took place in November 2019. The team held multiple workshops to identify technology gaps across the business and to create a five-year roadmap.

The top-ranked priorities were:

- Digitizing manual, manufacturing processes

- Establishing a global reporting system

- Upgrading quality management and operations management systems

- Integrating with a safety compliance system

The plan, according to Shahidan, was to start with simpler business processes and, “along the way, we manage to start to develop more complex systems using low-code.”

Better Data, More Automation

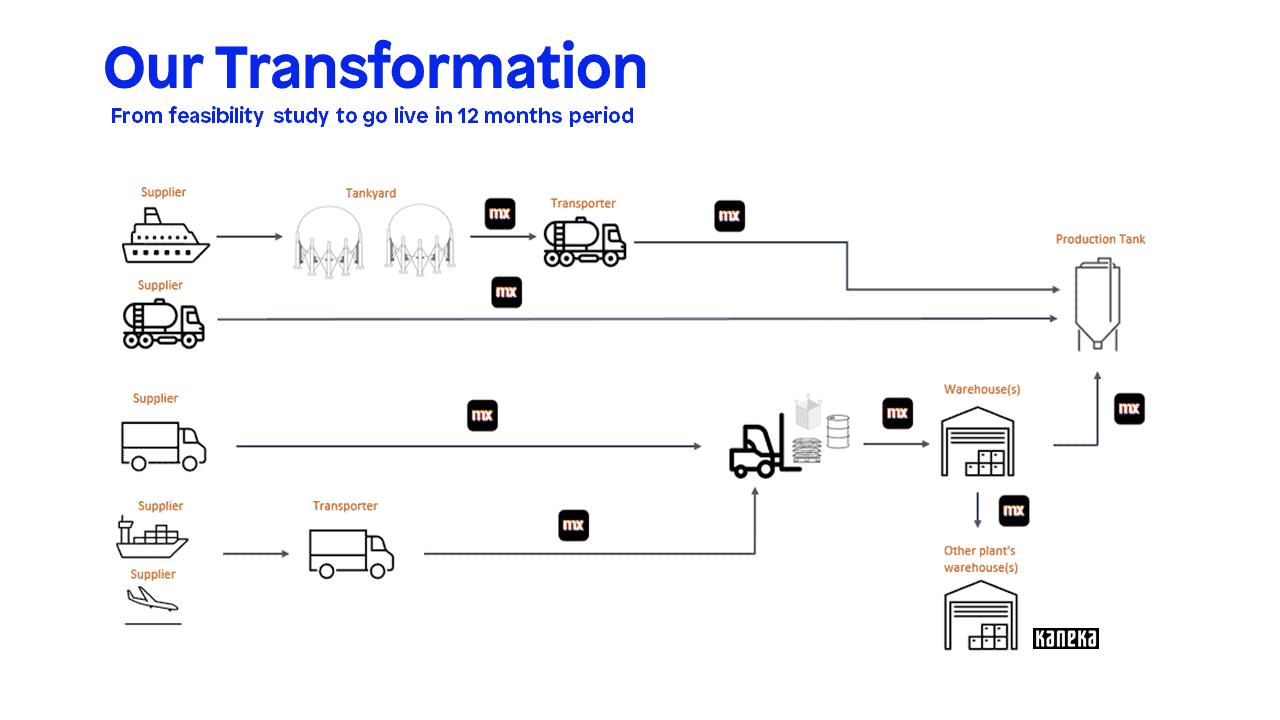

One of the first areas of focus for Kaneka was their raw material management system. This platform is used to manage raw material from receiving up through inventory management. Shahidan noted that this system’s receiving calendar “is the main reference for everybody to know what will be coming in our company,” so it was a project with huge visibility.

The north star for this particular project is better and more centralized data. Previously, records were kept on a combination of paper and forms such as Excel spreadsheets. In addition, the same data had to be input in different places at different points in the month, leading to redundant processes, lost time, and increased risk of error.

The IT project team was comprised of only 2 people, and they started by creating a feasibility study and interviewing management.

The team faced not only the technical challenge of developing a solution, but, according to Shahidan, “the bigger challenge is actually to manage the adoption for our users…We need to help them to change their culture in doing things.” These early discussions helped to create a sense of shared ownership and stakeholder buy-in.

Within 12 months of kickoff, the app was developed and released, creating a connected network between Kaneka’s employees and suppliers and showing the path from transport all the way to the production tank.

Because the app can be utilized on any device, Kaneka employees can use a tablet to enter data at any point, saving the need for paper or Excel. Because all data is processed through the app, Kaneka employees are confident in its veracity. Now that data is available in real-time, reporting and decision-making are faster than ever.

This combination of process automation, data validation, and multi-channel form factors has yielded a time savings of 100% in their reporting process and has eliminated the use of Excel and paper for production and logistics teams.

Application Development Yields 95% Time Savings

Kaneka’s development team also built a new quality management system in just three weeks. This system includes:

- Modules for inspection results, data analysis, and product certification

- Monitoring capabilities for employees to verify the quality of goods and sign off before they’re sent off to customers

Before this new application, lab employees would have to travel to the office to check progress and sign off. To reduce this significant inefficiency, the development team created a system that can be accessed anywhere, at any time, and by any device.

“By having this automation,” Shahidan explained, “the lab member who needs to approve or [sign] the certificate, doesn’t have to travel from their place to the office anymore.”

Developed in just a few weeks, the project resulted in a fantastic 86% time savings for inspectors during the week, and an even better 96% savings on the weekends. Further, by allowing employees to access the app through their mobile devices away from the office, Kaneka increased employee satisfaction by reducing the number of unnecessary trips to the office.

Empowering Development Across the Organization

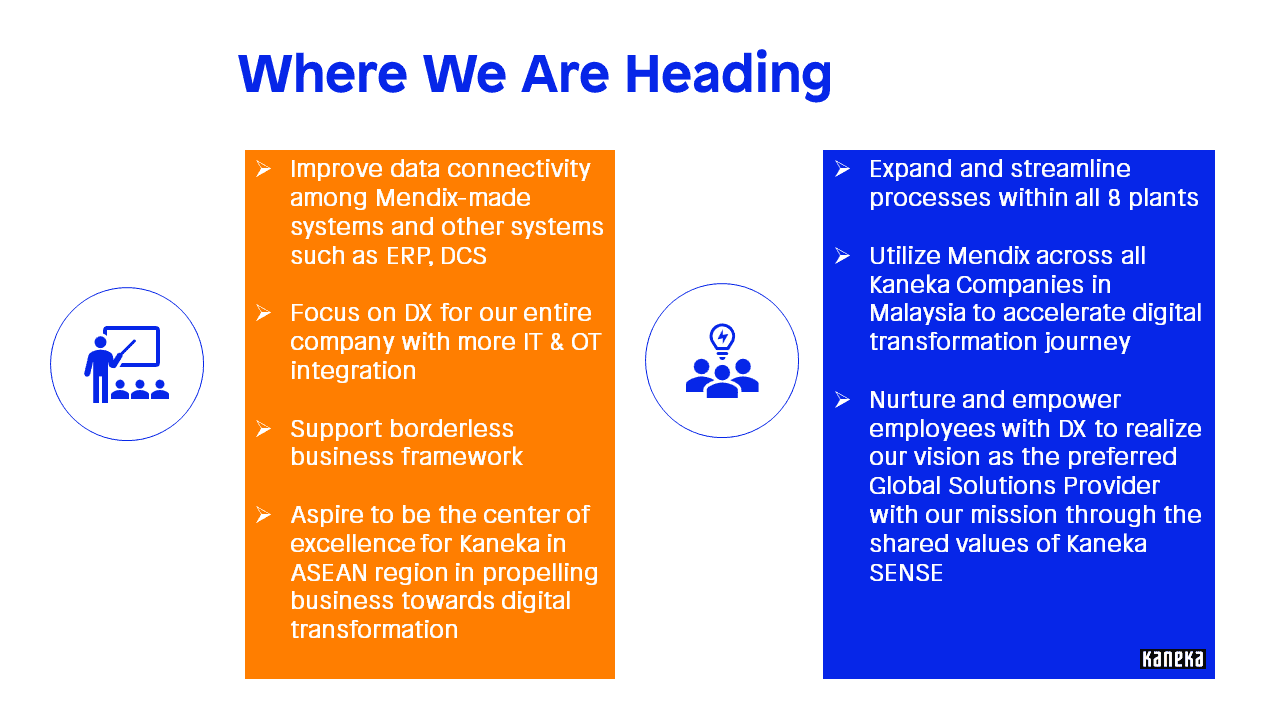

Empowered by their early success with low-code, Kaneka is piloting a new initiative, the Citizen Developers Program. This program is designed to give non-technical employees the knowledge and empowerment to become Mendix developers.

Starting with a pilot program in June 2021, Kaneka employees are trained in Mendix and asked to think about what they could develop to improve their day-to-day. To date, they’ve already seen a successful build around production-related inventory.

No one knows an employee’s specific work pain points better than they do themselves, and enabling employees to own the opportunity to improve and develop a solution in low-code will help digitize more of their manual processes than previously possible and continue to help transform their work culture.

“Tremendous Improvement”

In just over 18 months, Kaneka has used Mendix to automate 55 manual processes and build 13 new systems. These are just Kaneka’s first steps as they look to accelerate their digital transformation journey.

Among their next priorities is to improve data connectivity between their Mendix-built solutions and their existing ERP and DCS systems.

The team continues to focus on building internal expertise, using Mendix to help streamline processes across all plants. They also aspire for Kaneka Malaysia to be Kaneka’s ASEAN regional center of excellence for driving digital change.

For Kaneka, low-code has provided the opportunity not just to build solutions, but to drive real change in their organization. They’re very much on the way to their mission of, as Nishimoto stated, “nurturing and empowering our human capital with digital transformation to realize our vision as a preferred global solution provider.”