Digitizing Maritime Condition Monitoring with Royal IHC

Royal IHC is a leading provider of maritime vessels, equipment, and services. The Dutch-based organization is a world leader in the dredging industry, and also has a strong customer base in off-shore energy, mining, and defense. They have over 3,000 employees and reported revenues of €737.7 million in 2020.

The organization’s focus point is “operational efficiency, so making sure that our customers get maximum output with a minimum amount of resources,” said Laura Zwaan, Product Owner, Digital Business. Having delivered approximately 2,350 projects valued at more than €50 million since 2000, efficiency at scale is key to Royal IHC’s operations.

Because Royal IHC is working in ecosystems such as dredging and energy, they are also committed to building a more sustainable future. Creating efficiencies and optimizing processes through innovation is allowing Royal IHC to better understand present and future impact.

Royal IHC’s key values are commitment, partnership, and innovation to help customers. They recently faced a challenge with one of their key customer-facing services, which provided an opportunity to focus on customer-centric innovation. Zwaan joined Mendix World 2021 to show how low-code helped propel that opportunity into reality.

Identifying a Spot for Digital Innovation

Condition monitoring services are a central feature that Royal IHC offers to its customers. Zwaan described condition monitoring as services “in which we monitor a parameter of condition in order to project the state of the machinery, and also to see a significant change.” As examples, monitoring points such as temperature and vibration can help proactively identify maintenance needs and minimize unexpected downtime.

Until recently, the process has moved slowly, owing in part to the sometimes-remote location of IHC customer vessels. The crew on board a vessel would record the data and be responsible for getting the data to IHC. Data could come from different sources, including email and file transfers. “Sometimes,” said Zwaan, “we even needed to get the data through USB sticks, if we would even get it at all.” This led to incomplete data and reports being delivered via PDF on a quarterly basis. IHC recognized that they needed to digitize this process in order to ensure complete data and timely reporting. “It’s essential for us to deliver the service and to deliver value to the customer,” Zwaan related.

Working out of the Problem Space

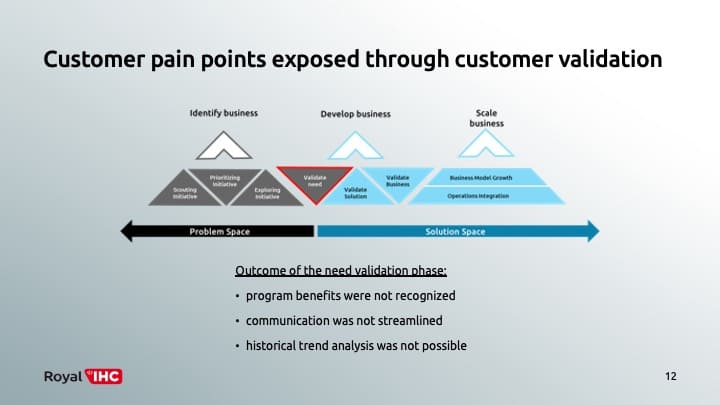

To get to a new solution, IHC instituted a 3-stage digital innovation process. The first stage is “Identify business,” where the team would scout, prioritize, and validate need. They also call this the Problem Space.

For IHC, this first part of the process involved speaking with a lot of customers and validating the need for digitization. For condition monitoring, some of the common themes were:

- Realizing program benefits: Zwann noted that customers “mentioned to us that program benefits were not always recognized. So that means they were spending an amount of money to pay for the services yearly, but it was very hard for them to feed back to their stakeholders what was actually the benefits achieved.”

- Communication: Because of the amount of resources needed to collect and send data back and forth, communication between IHC and customers was often confusing.

- Historical analysis: IHC was able to provide quarterly PDF reports, but, if customers wanted to analyze and see trends, they had to build manually.

These discussions with customers clarified with IHC that they needed to create a new digital solution to improve customer experience and meet their needs.

Validating a Solution with Low-code

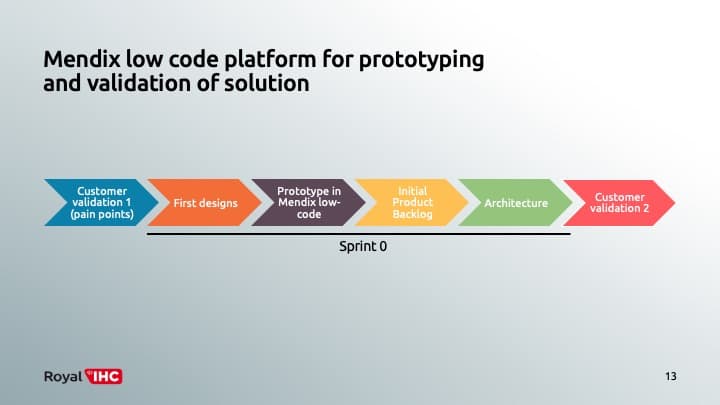

The next phases of IHC’s digital innovation process are developing and scaling their business, also known as the Solution Space. The Solution Space involves delivering solutions quickly, rapid iteration, and developing a customer interface. Due to their desire to move quickly and involve customers in a collaborative way, working in low-code with Mendix was a natural fit.

Using their customer needs as a North Star, the team at IHC took existing data to create a “quick Mendix low-code prototype so that we could already show customers how we translated their ideas into technology.” In just four days, IHC created designs, architecture and delivered the initial prototype.

Within the new app, data gathering, communication and task management have been greatly simplified. “Instead of emails, we moved to a task management system, which we built all in Mendix,” Zwaan reported. “And the customer now immediately sees what he needs to do.” Users are given all necessary information, including tasks and due dates, right on screen.

The new app also addresses concerns about data and value. The team built out dashboards based on KPIs that had come directly out of their customer conversations, meaning that they were supplying the solutions customers wanted the most. At a glance, a user can now see IHC advice based on any particular data point, success rates, times and categories. “The reasons why we give categories and percentages is because every customer puts another monetary value on a saving,” Zwaan reported. “For example, electrical faults, the customer now knows how many [potential issues], [what] percentage of those [issues] were electrical faults. And, then, he can put his monetary value and communicate to his stakeholders.”

The team also accounted for the need around historical data analysis, creating a condition table and chart which can be used to compare different vessels across different time periods. Zwaan described, “The customer can select his time periods, his fleet, and also the vessels he wants to compare…and then choose the machines he wants to compare. He can immediately see what the difference is.” The app also provides charts, giving vessel captains the ability to do a complete self-analysis.

New Business, Increased Satisfaction

“So what did we actually get back from this investment [in] digital innovation?,” Zwaan asked. “Customers actually decided to renew their contracts with us.” Based on the new condition monitoring application, IHC was able to renew annual contracts on 19 vessels. In addition, having a new digital experience to demo resulted in contracts with 4 new vessels as well.

On top of that business value, “customers really appreciated that we didn’t push the technology on them, but that we got their feedback in every step,” according to Zwaan. These more satisfied customers gave several public endorsements to IHC.

In addition, IHC also gained internal efficiencies. By moving to this new system and having it run much more smoothly, IHC was able to realize a yearly savings of one full-time employee.

Being Responsive to Customer Needs

IHC learned a lot of things from their digitization experience that they are taking into future projects:

- Customer first and customer always: Validating need with customers gave IHC clear goals and ensured that they were investing in a solution that customers would want and use. Whenever discussions would happen about direction, IHC always turned back to the customer’s needs as the top priority.

- Involve customers early and often: “Internally, people were afraid that we needed to really show the customer already a done product or a done service and really have something to offer, but that is not the case,” Zwaan reported. IHC’s customers appreciated being part of the conversation and being able to input into future direction.

- Build solutions in small steps: IHC realized that taking all customer needs and building to them would be expensive and may not be the right fit. They chose to focus on small chunks and get customer feedback. This, coupled with the Mendix low-code platform, was the perfect way to increase flexibility. “Digital is not about big change,” Zwaan stated, “but also about small improvements…addressing these pain points with even small digital means building search platforms in Mendix low-code can really help the customer.”

For Royal IHC, digitizing their condition monitoring process was an enormous win for the organization that didn’t take a year or even a quarter. Using low-code, IHC delivered true value to their customers in under a month. This quick development has allowed IHC to meet customer needs, retain and win business and maintain their place as a market leader. They are also more confident and better positioned for further low-code development to meet customer demand. As Zwaan noted, “Whatever the customer wants, that is what we will do.”