SAIC Motor’s Path to Data-Driven Automotive Innovation with Mendix

Shanghai Automotive Group Co., Ltd. (SAIC Motor) is the largest automobile listed company in China’s domestic market.

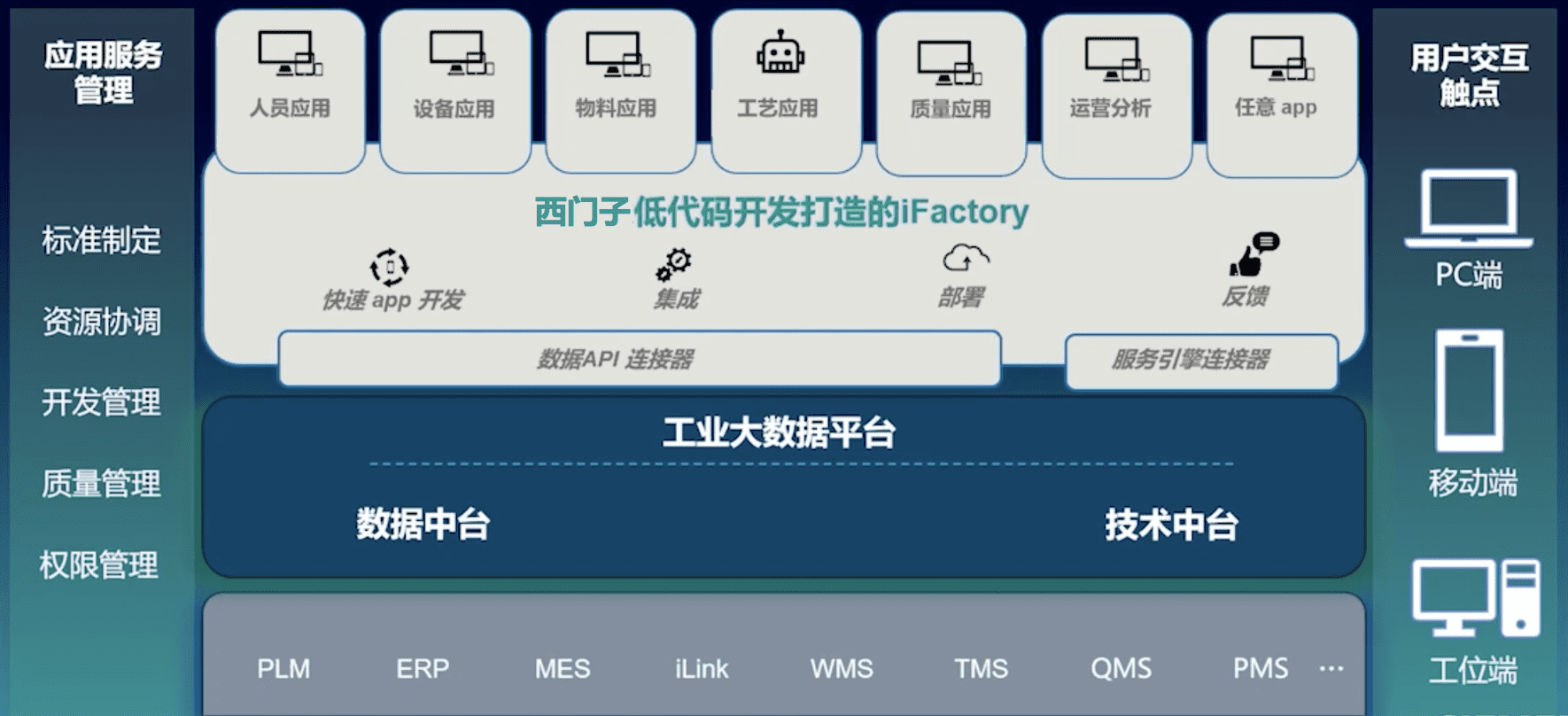

As the sector shifts toward intelligent connectivity, SAIC has embraced new technologies with the goal of becoming a high-tech automotive leader. To support this vision, the company established robust IT systems like ERP, PLM, WMS, QMS, and iMES, which form the backbone of its core operations.

To accelerate its digital transformation, SAIC Motor introduced the “1+4” initiative, focusing on product digitization along with digital R&D, Marketing, and Intelligent Manufacturing. The company aims to create software-defined vehicles, digital twins, and intelligent factories as part of this vision.

“The vision of becoming a high-tech automotive company involves three steps: full digital transformation, becoming a software-driven enterprise, and leveraging our digital capabilities to empower the entire supply chain,” shared Yang Min, director of Data and Information Systems.

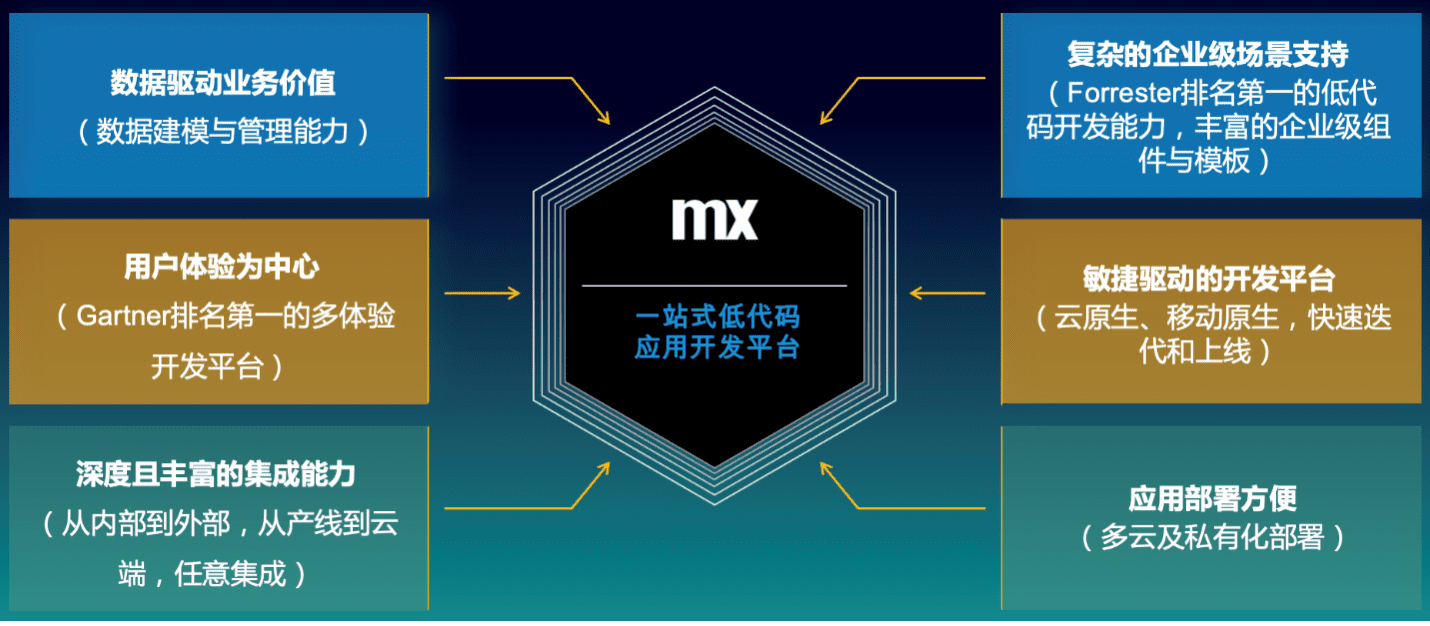

To meet these ambitious goals, SAIC Motor adopted the Mendix development platform in 2020, and has since transformed its IT capabilities, operational processes, and digital ecosystem.

Unlocking Agile and Flexible IT Development

By leveraging innovative technologies like Mendix, SAIC Motor saw an opportunity to save time and costs while enhancing user experience and operational efficiency. Low-code not only accelerated development but also helped unify its supply chain, smart factories, and digital marketing into a cohesive, agile, and responsive ecosystem.

Furthermore, before adopting Mendix, SAIC Motor faced several challenges with its Quality Management System (QMS), including:

- Coordinating downtime for system upgrades: Multi-site upgrades required simultaneous downtime, which was nearly impossible given the ongoing production schedules.

- High demands for interface responsiveness: Tools like PDA devices on production lines needed to perform at high speed to keep up with manufacturing workflows.

- Lack of unified management standards: Despite sharing the same quality standard (TF16949), different sites focused on varying aspects, such as process management and post-production audits.

To tackle these challenges and push forward its “1+4” initiative, SAIC Motor decided to rebuild its QMS. After evaluating Mendix and low-code against traditional Java development, the team chose Mendix for its reusability, flexibility, and agility.

Mendix exceeded expectations through several of SAIC Motor’s tests and proof-of-concept (POC) projects, including online order systems, contract management, high-concurrency stress testing, and large data import/export.

“Low-code could greatly accelerate the QMS system rebuild,” shared Sheng Fei, QMS product manager at SAIC Motor.

Mendix also provided SAIC Motor with:

- Faster, clearer communication of requirements: Web-based Create, Read, Update, and Delete (CRUD) operations and low-code development improved efficiency and sped up delivery.

- Hot deployment capability: Updates could be deployed without downtime, eliminating the need for multi-site coordination.

- Seamless integration: Mendix applications integrated smoothly with the existing Java framework, maximizing resource efficiency.

Transforming Core Business Operations

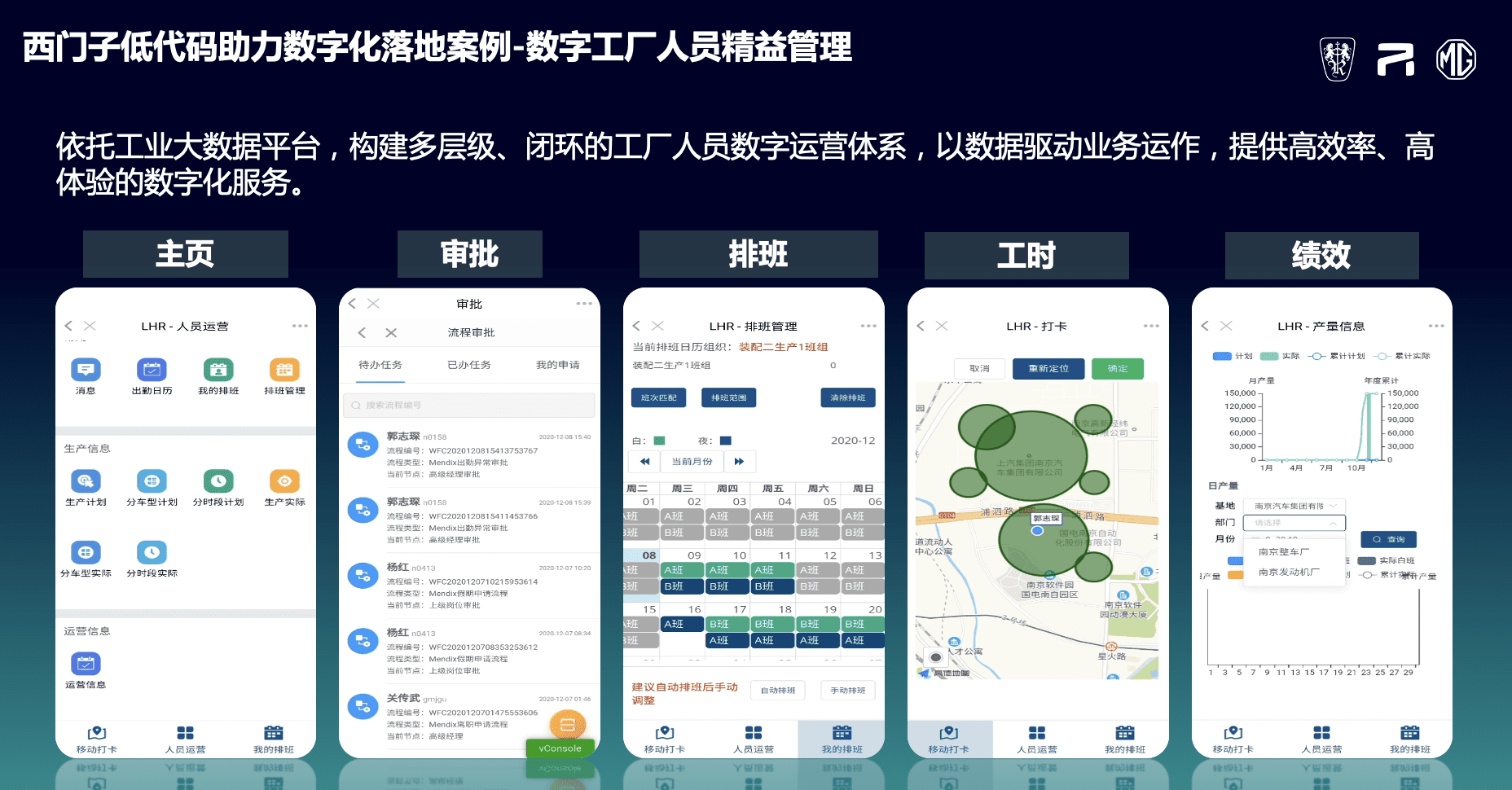

Since adopting Mendix, SAIC Motor has successfully integrated the platform into its IT stack, completing projects ranging from HR solutions to time-tracking systems.

One notable example is the Lean Workforce Management System, developed primarily by HR. This system efficiently met internal process needs without heavy IT involvement, empowering business users to lead the project.

Similarly, the Shortage Vehicle Management System was developed in just two weeks, enabling the company to respond quickly to dynamic business requirements.

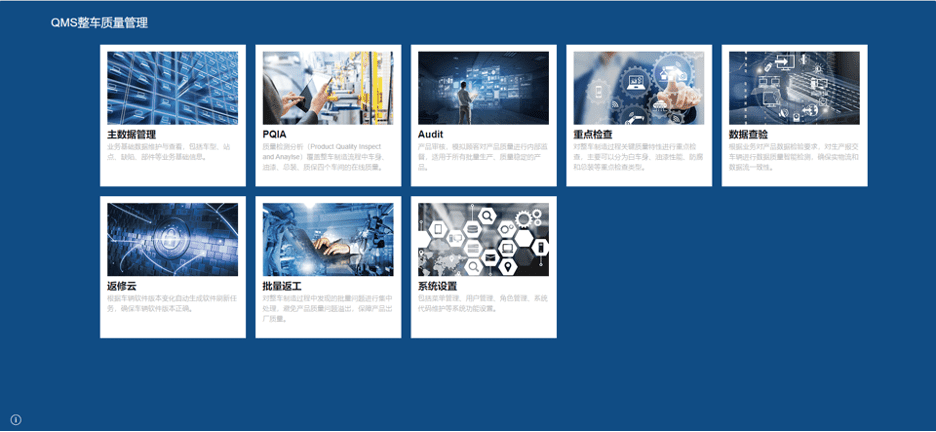

Rebuilding QMS System Architecture

SAIC Motor’s Mendix-built QMS has replaced a legacy system with a more agile, customizable solution. Previously, system updates required downtime and overnight IT work, often taking 6–7 hours. Deployment issues led to rollbacks, causing delays.

With Mendix, hot deployment allows for daily updates without downtime, minimizing disruption to operations. Business users now experience seamless updates without interruptions.

SAIC Motor’s new, low-code QMS system offers the following core features:

- Product Defect Management

- Repair Management

- Vehicle Handover

- Key Inspections

- Customizable Reports

The system is built on a cloud-and-edge architecture with Mendix, offering centralized components and enhanced scalability for future projects. Functions like reporting and master data management, along with product quality inspections, are housed in the new system.

Additionally, with Mendix, SAIC Motor’s QMS system now integrates seamlessly with the existing Java-based framework with:

- iFrame Connector: Mendix pages were embedded within iFrames with independent authentication for single sign-on. This approach ensured low coupling, system stability, and a unified user experience.

- Permission Management: Java handled page visibility, while Mendix managed granular button-level permissions, taking advantage of the strengths of both platforms.

Scaling Low-Code Innovation at SAIC Motor

SAIC Motor’s journey with Mendix highlights the critical role of redefining IT in automotive manufacturing by:

- Improving personnel capabilities: Empowering business users to actively participate in the development process.

- Shortening delivery cycles: Leveraging efficient low-code tools for faster project execution.

- Gaining recognition and acceptance: Building support across both IT and business units.

- Creating new opportunities for innovation: Encouraging fresh thinking within traditional enterprises.

- Facilitating rapid iteration: Enabling agile, comprehensive digital transformation.

In addition, SAIC Motor established a component center with over 40 reusable modules in less than a year, significantly boosting development speed, reducing costs, and helping realize its “1+4” initiative.

Today, SAIC Motor continues to innovate and expand its digital footprint, leveraging Mendix’s agility to tackle new challenges and opportunities.