Mendix for Aerospace & Defense

OEMs and suppliers need to keep pace with evolving customer expectations, shifting global powers, and changing industry dynamics.

Explore MarketplaceFacing the shadow of technology

Accelerate innovation and increase efficiency to meet rising customer expectations and growing program complexities.

-

New market players need to differentiate

Technology is making the industry accessible to new players, placing increased pressure on incumbents to revolutionize their R&D practices. Established providers need to invest in order to differentiate themselves.

-

Demand exceeds rate of supply

Additive manufacturing is increasingly becoming a valued part of the production process as its reliability improves. Giving OEMs the freedom to produce parts on demand.

-

Aging workforce stalls innovation

There is a growing skills gap to manage legacy systems in languages that are no longer used as the experts near the end of the careers. Skills shortages, a lack of new talent, and rising training costs i are stifling innovation and growth.

-

Growing data siloes fuels data chaos

Siloed data creates a problem on two fronts. Data saved in multiple locations is difficult to govern and locate, which increases inefficiency and risk. If your data is organized and easily accessible it makes it more difficult to analyze effectively, leaving you at a disadvantage when it comes to making data-driven decisions.

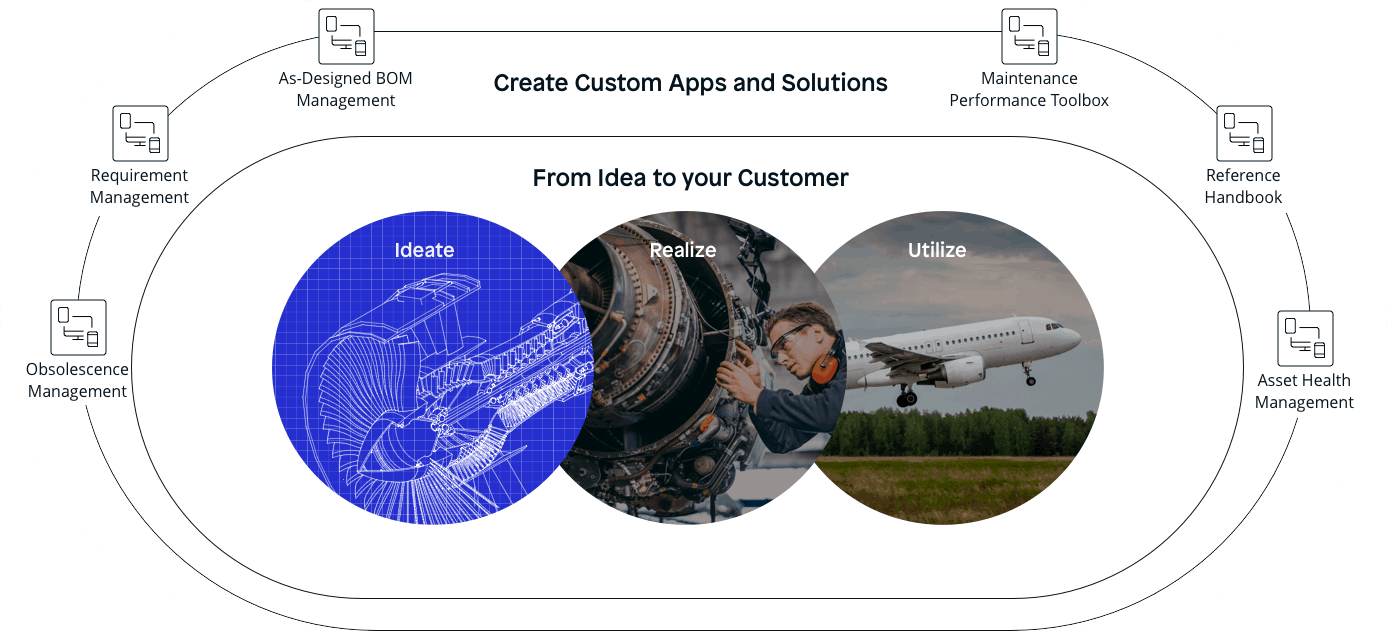

Low-code enables adaptive flexibility

Mendix helps leading aerospace & defense companies find innovative ways to minimize costs and cut time to market, while optimizing product performance.

The digital twin is a precise virtual model of a product or a production plant. It displays development throughout the entire lifecycle and allows operators to predict behavior, optimize performance, and implement insights from previous design and production experiences.

You can gain tremendous value from exploring “What if?” scenarios and predicting future performance with the digital twin. The ultimate goal of the digital twin is in the closed-loop connection between the virtual world of product development and production planning with the physical world of production system and product performance.

Through this connection you can gain actionable insight from the physical world that wilt fuel informed decisions throughout the lifecycle of products and production operations.