How sharp is your competitive edge?

Outdistance your peers with low-code

Explore MarketplaceLegacy Lag Costs You Big

It’s Broken and You Need to Fix It

-

Legacy systems can't keep up

Energy sources are shifting, the regulatory landscape is getting more complex, and customers are expecting more personalized products.

Operating business-critical operations on legacy systems that can’t function with new technologies like AI, ML, IoT, and distributed ledger is stifling your ability to evolve at the pace your industry requires.

-

Mired in data chaos

Siloed data spread across geographies and stored in a mix of on-premises servers and data centers hamstrings effective data analytics and puts you at a high risk for noncompliance with data privacy laws or a breach.

-

End-to-end problems

A data analyst in your corporate headquarters and a marine operations manager in the Pacific Ocean would have vastly different problems.

But both issues would negatively impact your business and they both need solutions that fit their specific needs.

-

Digital Productivity Mobile Enhancement

One department or one extraction facility that uses an outdated spreadsheet or manual process doesn’t sound like a big deal.

But, it’s never just one. All the manual processes, internal fixes, and “temporary” workarounds cause almost incalculable inefficiencies, backlogs, and user errors wasting time and costing you money.

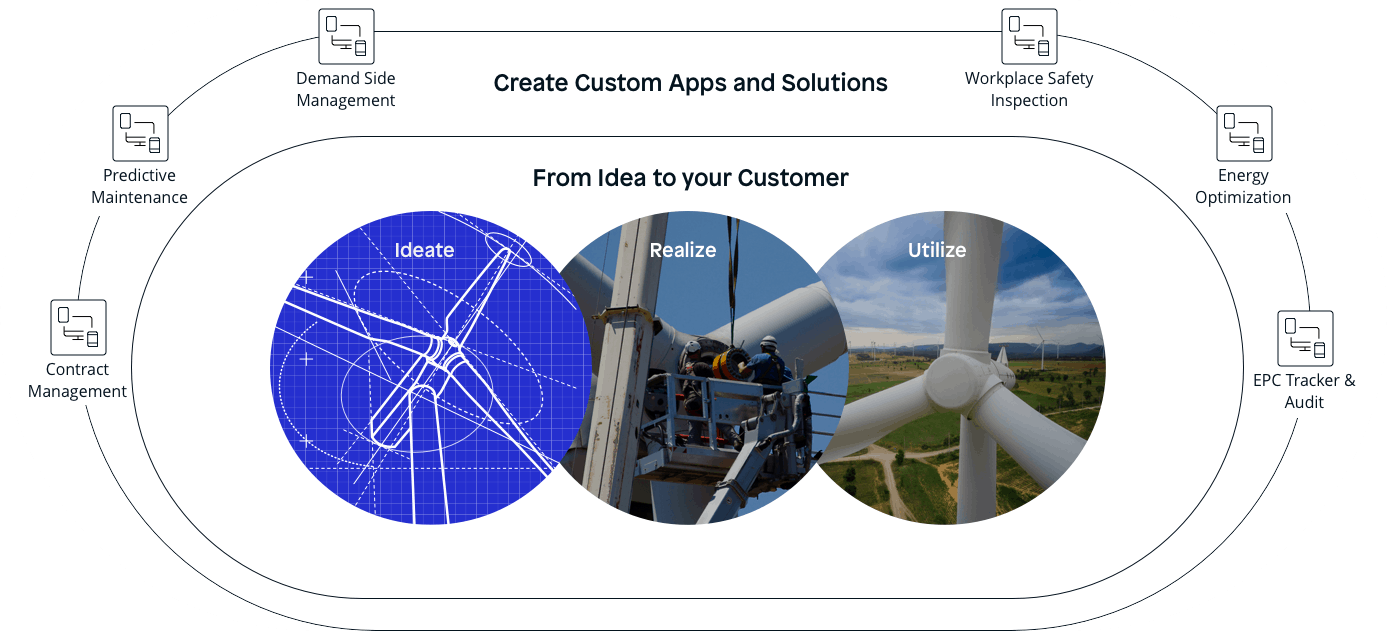

Evolve with Mendix

Energy and utility companies are using Mendix to keep pace in a rapidly evolving digital landscape.

The digital twin is a precise virtual model of a product or a production plant. It displays development throughout the entire lifecycle and allows operators to predict behavior, optimize performance, and implement insights from previous design and production experiences.

You can gain tremendous value from exploring “What if?” scenarios and predicting future performance with the digital twin. The ultimate goal of the digital twin is in the closed-loop connection between the virtual world of product development and production planning with the physical world of production system and product performance.

Through this connection you can gain actionable insight from the physical world that wilt fuel informed decisions throughout the lifecycle of products and production operations.