Smart Connected Buildings

Gain real-time insight into how your building or properties are functioning and operating. Analytics and machine learning work together to provide suggestions for improvements and the option to automate preventative maintenance.

-

Dashboard Controls

Review conditions inside your factory or office in real time. Make timely adjustments for noise, vibration, air quality and other factors based on active data from onsite sensors.

-

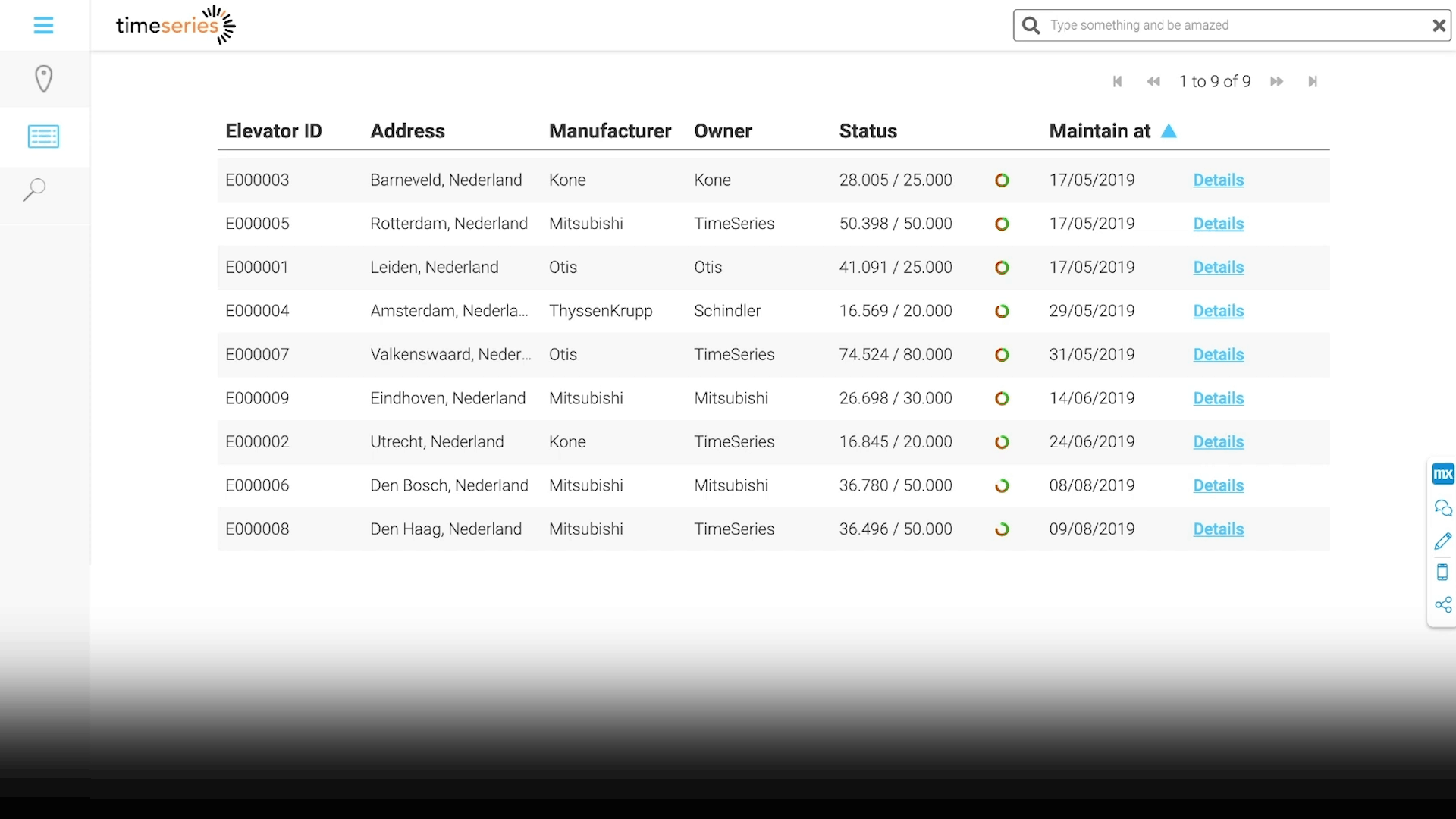

Predictive Maintenance

Machine learning and your data work together to predict what maintenance is needed where and when. Prioritize repairs and replacements before secondary issues occur.

-

A Single Pane of Glass

Grant access to sensor data on role-based dashboards as needed.

-

Advanced Analytics

Determine a property’s operational and energy efficiency using aggregate structured and unstructured as well as current and historic data from multiple sources.

Key Solution Capabilities

-

An Open and Extensible Platform

The open platform allows the solution to integrate into your existing building management landscape. Combine best-in-class technology stacks to create a unified view of your real estate holdings.

-

Modular and Flexible

Smart Connected Buildings can be customized to your needs and processes. Use pre-built components or create bespoke features.

-

User Experience

Designed with simplicity in mind, minimize the effort required to provide training and enablement. Role-based, contextual guidance provides just-in-time nudges to guide the operator on what needs to be done on particular application screens.

Use Case

Octo Delivers Smart Building Insights with Low-Code and AI

Using the Mendix platform Octo:

- cut development time for new features by 96%

- easily integrates with open source libraries and AI technology

- transformed their consulting services to a business

Ready to get started with this solution?

Fill this out and we’ll reach out shortly.